10 Apr A complete guide to VHP Passbox for your Containment System.

VHP decontamination systems are becoming increasingly important as regulators turn their focus away from the frequently used Steam and Dry Heat Sterilization methods in order to reduce the risk of cross-contamination and bio-burden.

The VHP Passbox is used to introduce materials into the sterile area that cannot be sterilized in an autoclave. This is made feasible by VHP’s broad spectrum of microbicidal characteristics and compatibility with the majority of sterile processing materials. Finally, and most importantly, the VHP breaks into water and oxygen, so it can be safely disposed of.

Uses of VHP Passbox:

It is used to bring into sterile regions all things that cannot be sterilized in an autoclave, typically: heat sensitive products such as sterile petri-dishes; sterile materials for validation or cleaning operations, such as disinfectants; electronic particle meters; clothes, and so on.

It is also commonly used to decontaminate daily manufacturing items that cannot be sterilized using steam, such as rubber stopper bags and API aluminum containers.

Working of VHP Passbox:

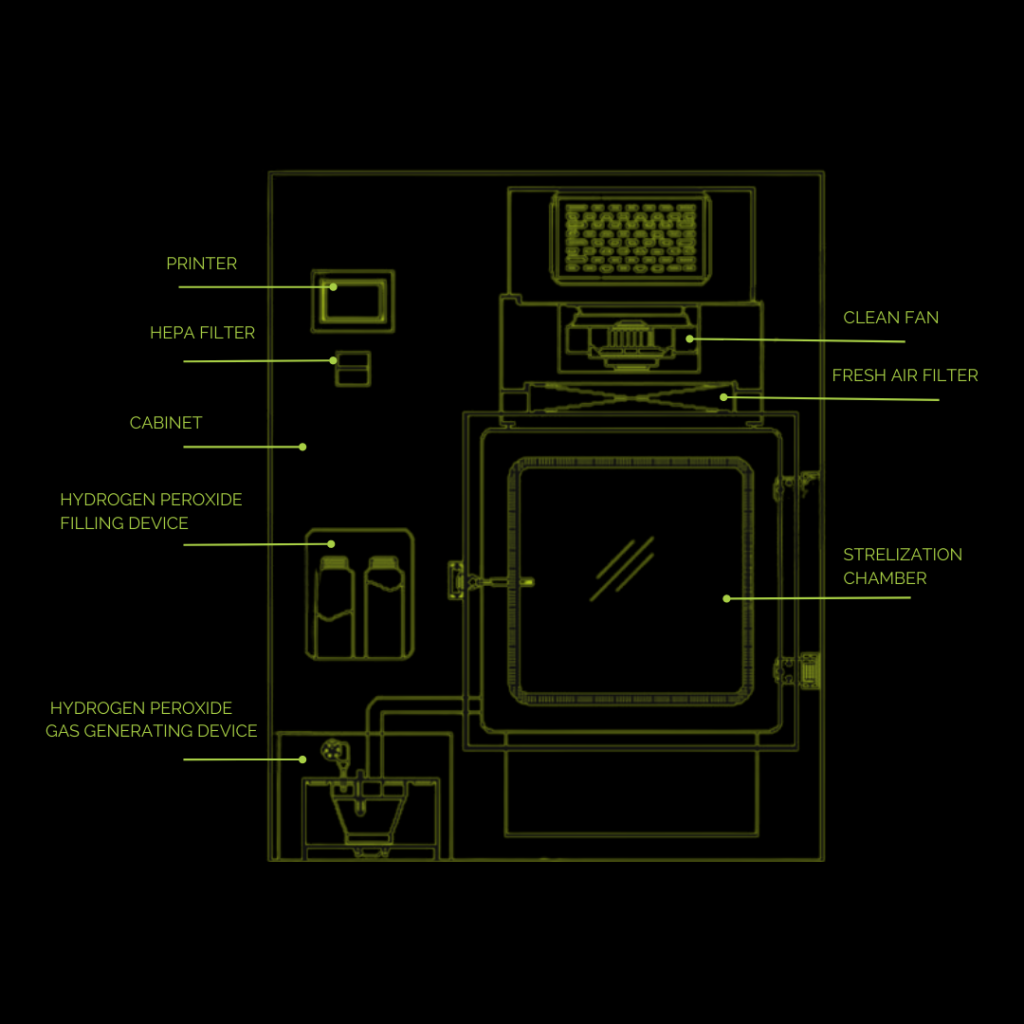

The VHP Passbox works by using a process called Vaporized Hydrogen Peroxide (VHP) decontamination. The Passbox consists of two chambers separated by a door or iris mechanism, which allows material to be transferred from one chamber to the other.

Before the transfer process, the VHP Passbox is first cleaned and sealed. Then, the VHP decontamination process is initiated by injecting hydrogen peroxide vapor into the Passbox chamber, which reaches all surfaces and materials inside the chamber, including the material to be transferred.

The hydrogen peroxide vapor then reacts with and eliminates any microbial or viral contamination present on the surface of the material. After a predetermined exposure time, the hydrogen peroxide is then removed by aeration and the material is safe to be transferred into the cleanroom or controlled environment.

The VHP Passbox is typically used in pharmaceutical manufacturing, biotechnology, and other industries that require a high level of cleanliness to prevent contamination of products and processes.

Process of VHP Passbox Decontamination:

A built-in VHP generator inside the VHP Passbox heats up the hydrogen peroxide, converting it from liquid to vapor. The vaporized hydrogen peroxide is blown into the chamber which creates a sterile environment capable of killing bacteria, virus, and fungi.

The working process of VHP Passbox include these 4 stages:

Dehumidification:

This operation will circulate the air in the cavity via the dehumidifier, lowering the relative humidity within the VHP pass box chamber in preparation for the best VHP sterilization efficiency.

Condition:

To rapidly raise the concentration of vaporized hydrogen peroxide in its chamber, the VHP generator rapidly introduces hydrogen peroxide vapor into the chamber of the VHP pass box.

Decontamination:

The VHP generator slowly delivers hydrogen peroxide vapor into the VHP pass box chamber to maintain a certain concentration and cleanse the chamber.

Ventilation and debris removal:

After sterilization, the vaporized hydrogen peroxide within the cleanroom door is removed until the concentration is less than 1 ppm.

Features of VHP Passbox:

- The VHP pass box’s overall construction is 304 stainless steel.

- VHP pass box employs an airtight twin door construction and an interlock system to ensure that two doors cannot be opened at the same time.

- To prevent contamination, the air entering and leaving the VHP pass box chamber is filtered by high-efficiency filters (HEPA – H14).

- The system monitors the temperature, humidity, pressure, and hydrogen peroxide content within the chamber in real time.

- In the functioning process, there are indication lights.

- The superior automated control system provides the stability and dependability of diverse VHP pass box processes.

In a nutshell:

The VHP Passbox is an essential piece of equipment for pharmaceutical and biotech manufacturing facilities that require a high level of sterility assurance. Its use ensures that materials are transferred between controlled environments without any risk of contamination, thus helping to maintain the integrity of the products being manufactured. The VHP Passbox is a cost-effective and customizable solution that provides a safe and efficient transfer process for sensitive materials.

Sorry, the comment form is closed at this time.