Isovax designs, supplies and validates transportable, table top and Standalone Containment equipment for the Pharmaceutical & Biotech Industry. Containment technology is becoming more popular as new pharmaceutical advancements emerge.

Isovax Technologies gives you the ability to regulate production processes in a confined environment. The ultimate goal is to safeguard the product, people, and the planet in case of excessive toxicity and product reactivity, ensuring maximum profitability in the long term.

Our Goal is to enable the highest level of innovation in dealing with high potent drugs for our customers thereby providing assured protection always while being Viable and Sustainable.

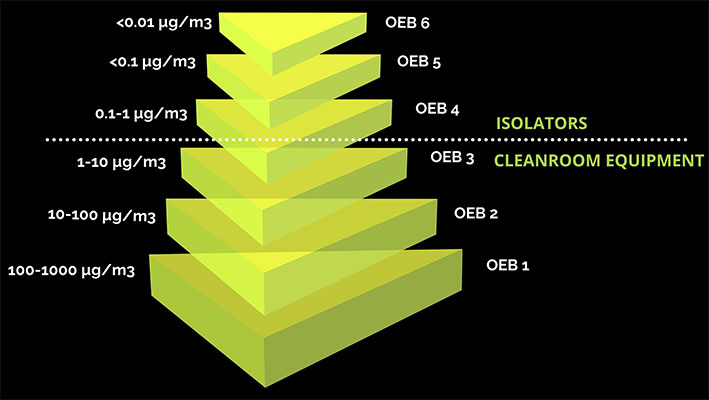

The Occupational Exposure Band (OEB) is a concept for classifying chemicals into “categories” or “bands” based on their adverse health effects and potency. It organizes compounds into groups based on OEL to establish safe handling standards.

OEB (Operator Exposure Band) categories represent the degree of toxicity of the chemical on a containment scale. On the other hand, the OEL (Operator Exposure Limit) indicates the average concentration of the active chemical in the air at workplace over a certain period of time during which the operator is unlikely to have acute or chronic health consequences.

At OEB level 5, the material is highly hazardous, hence significant measures are taken to prevent operator exposure. There is a permanent physical barrier between the operator and the material. Closed material handling and transfer is undertaken inside Isolators and Restricted-Access Barrier Systems (RABS) via glove ports. Even inside the isolator, material should be handled utilizing RTPs, split butterfly valves, other aseptic transfer systems, for contained handling.

ISOVAX provides isolators that have been technologically created to meet the stringent demands of your products and market.

Whether it’s highly potent molecules that need to be safeguarded or hazardous compounds that must be handled with operator safety.

We are prepared to provide a comprehensive set of integrated products and services to support the complete processing of your products requiring a high level of containment.