06 May DIFFERENCE BETWEEN RIGID AND FLEXIBLE ISOLATORS.

In our previous articles, we spoke about the difference between RABS and Isolators and OEB and OEL Levels.

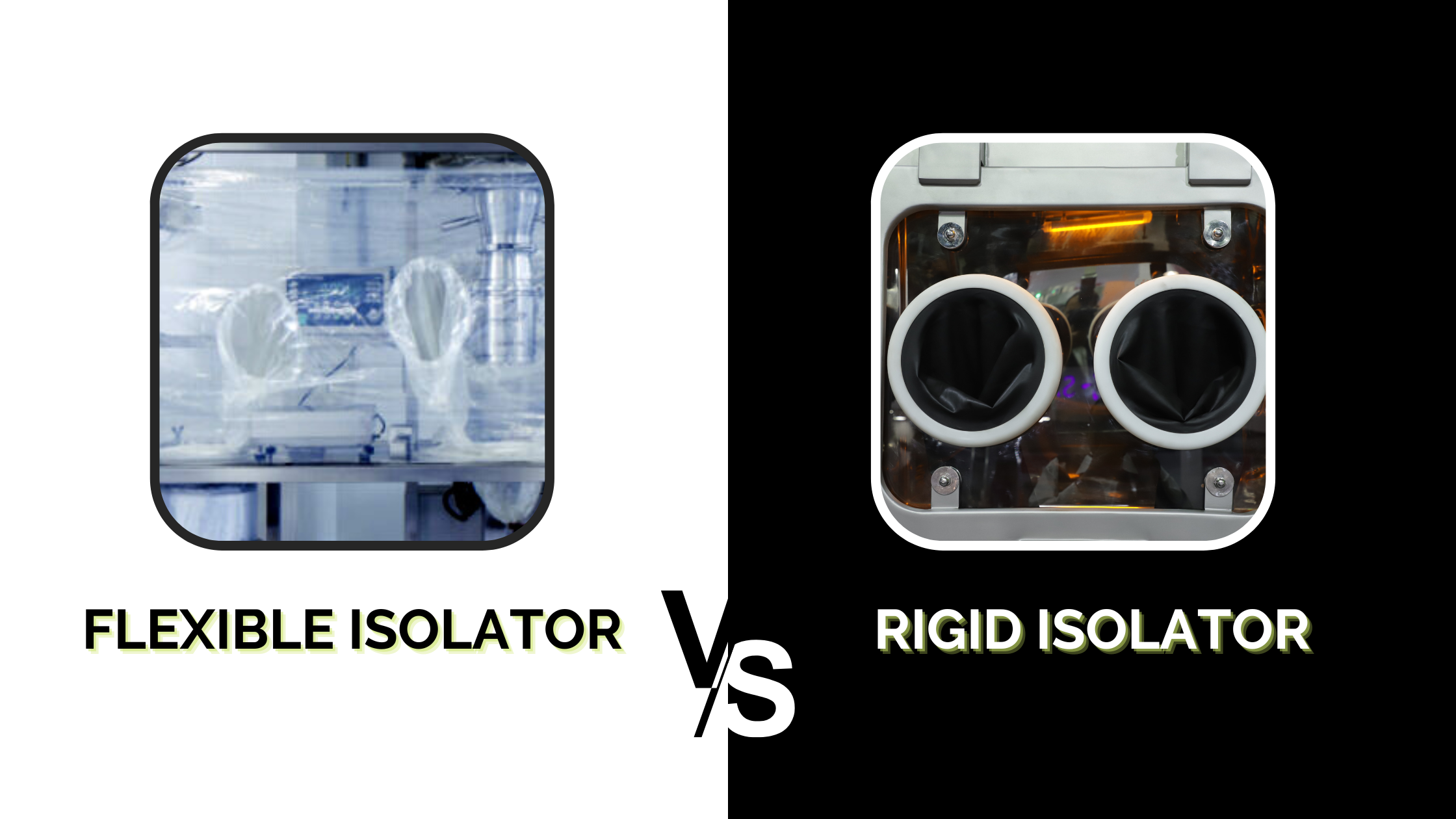

Since we have got the basic understanding of how RABS are different from Isolators, we’ll compare and contrast two of the most prevalent types of containment isolators: Flexible and Rigid Isolators.

Flexible Isolator:

A stainless steel bottom framework that supports a work table and a stainless steel top structure that supports the flexible enclosure are common components of flexible isolators.

Enclosures are commonly made of polyvinyl chloride or polyurethane.

Glove sleeves are often made of the same materials as the enclosure and are an integral part of it. The air is filtered at the inlet and output filters.

Blowers can create positive or negative air pressure, and ports or panels can be added to enable things to enter or exit the isolator.

These isolators are easy to set up, lightweight, and give good visibility and flexibility when working in gloves. They’ve been used for sterility testing and other aseptic procedures as well.

Flexible Containment Isolators offer higher containment requirements than Downflow Booth technology, and they frequently outperform Rigid Isolator systems. Flexible Isolators provide shorter lead times and cheaper prices than airflow Booths or Rigid Isolator systems, in addition to delivering excellent levels of operator safety. Flexible Isolators are frequently used in experimental or R&D applications where speed of deployment and operator safety are important considerations.

Rigid Isolator:

On the other hand, the rigid wall isolator is rigid. The enclosures of these isolators are normally built of 316L stainless steel with a laminated safety glass viewing window, despite the fact that they have a stainless steel frame.

Glove ports are situated near the glove sleeves on the glass. These isolators have a greater price tag than flexible isolators. Rigid isolators are essential where possible external contamination from the clean-room environment or personnel can not be allowed to enter the process media.

These positive pressure barrier isolators are generally more complex than our negative range and controlled by PLC or HMI control panels. During automatic operation, this type of isolator goes through its start-up sequence ensuring all checks are completed. It then conducts a decontamination operation by VHP and once successfully performs its auto switches to show an ‘isolator healthy’ operation ready for processing.

Rigid Containment Isolators have been designed for handling potent compounds that can offer guaranteed levels of operator protection as low as 10ng/m3 (task duration). These include designs for sampling, dispensing and sub-division, mixing and other applications.

Comparison:

| Parameters | Flexible | Rigid |

| Containment Effectiveness | High | High |

| Lead Time | Short | Long |

| Cost | Low Capital Cost | High Capital cost |

| Integration with existing equipment | Easy | Complex |

| Operational Handling | Difficult | Easy |

| Maintenance Cost | High | Low |

| Flexibility | Highly flexible | Inflexible |

| Intermittent Deployment | Yes | No |

| Negative Pressure | -30 pa typical+60 pa aseptic | No limited in Practice |

| Chemical Compatibility | Limited solvent resistance | High |

Chemical Compatibility:

Rigid isolators are often built of FDA-compliant inert materials like glass and stainless steel, and are designed to be cleaned with a variety of treatments. Chemical compatibility is rarely a problem. In rigid isolators, the enhanced level of solvent compatibility benefits in future-proofing the isolator. Rigid wall systems have a greater chance of being compatible in the future if the nature of the solvents required in the future is unknown at the time of specification.To neutralise the highly strong substance, the isolator can be washed with harsh chemicals as well.

Flexible isolators, on the other hand, are made of polymers, therefore when choosing cleaning chemicals, the material of construction must be compatible with the item being treated.Flexible film isolators will not withstand severe chemicals and will turn yellow after being cleaned with IPA.

Temperature Compatibility:

High temperatures are seldom a concern with rigid systems. Flexible isolators, on the other hand, may be more affected by temperature if high-temperature operations are anticipated.

Both rigid and flexible systems may require equipment to exhaust or cool the environment if the process requires it.

Advantages of Flexible Isolators

- Custom Designed

- Integration with Existing Equipment

- Improved Ergonomics

- Reduced Need for PPE

- Operator Friendly

- Effective Solution

A major issue in any flexible isolator design is the disposal of contaminated enclosures. Some may suggest that safety during disposal is solely dependent on adequate SOPs for clean-up and decontamination prior to enclosure removal, however depending on SOPs in such a crucial pass/fail situation when staff members may be contaminated by the enclosure disposal process is untenable. Especially when the API, or even worse, HPAPI, is a major security risk.

Advantages of Rigid Isolators:

- Greater operator protection.

- Resistant to harsh cleaning and neutralising chemicals

- Leak test is quick and easy

- In-situ change of gloves and sleeves

- Safe filter change inside the isolator

Summary

Containment Isolators (both rigid and flexible) are two of the containment methods accessible. The potency of the product, as well as the frequency of operations, the volume of material handled, and the material handling style, all impact the isolation technology used.

Sorry, the comment form is closed at this time.