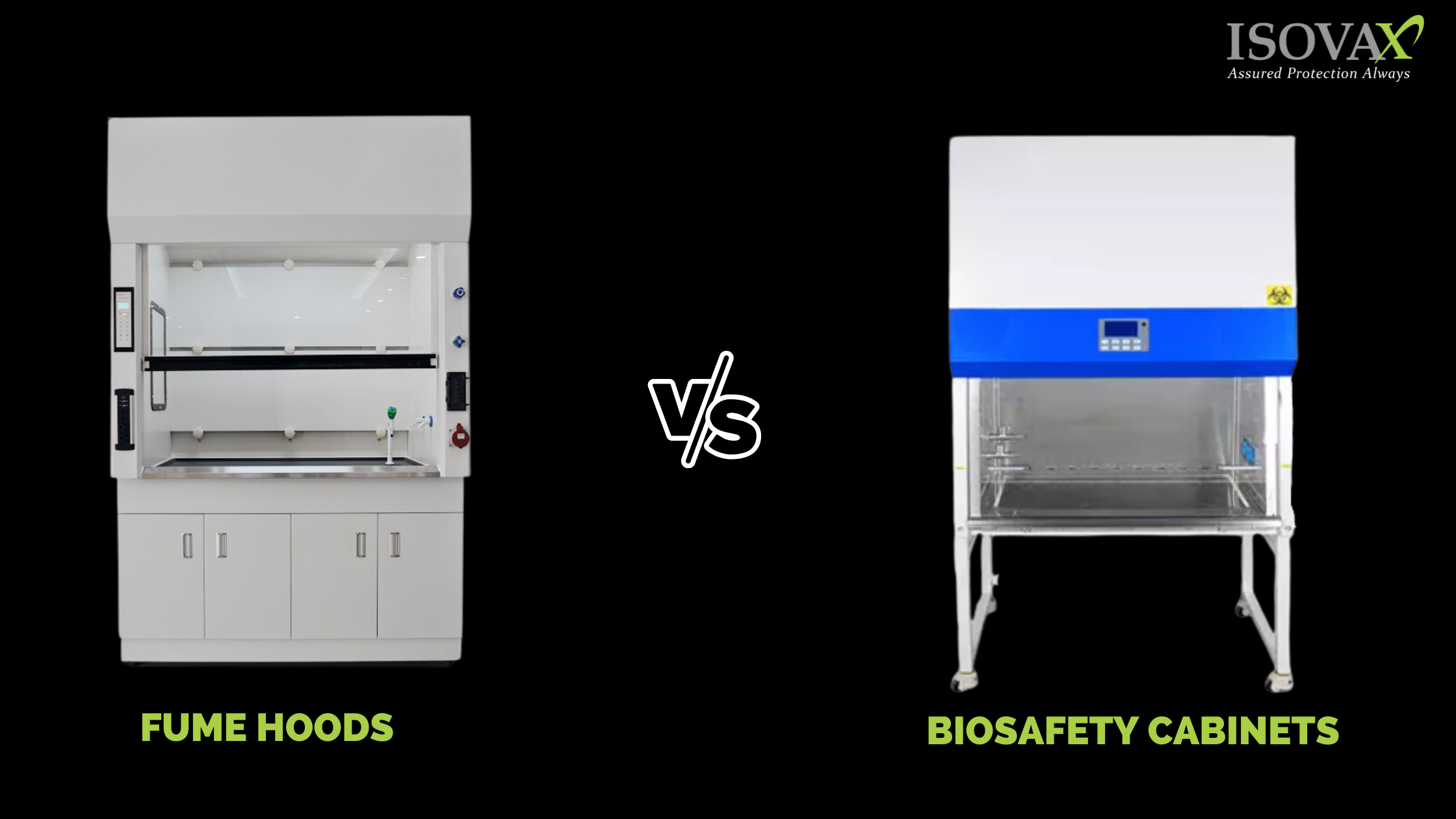

21 Jun Difference Between Fume Hoods and Biosafety Cabinets

Fume hoods and biosafety cabinets are two examples of lab equipment that may purify the air in the work area and rid it of toxic compounds, allowing lab staff to handle hazardous materials without being concerned about contamination. They are both well known in the healthcare, education, and medical fields. Although both fume hoods and biosafety cabinets shield lab workers from dangerous vapors, there are considerable differences in their design, purpose, and use. This article contrasts these two equipment types based on a variety of factors, including protection, airflow, appropriate uses, and variance. You can use this guide to determine which choice is best for you.

Distinctive Parameters:

Airflow:

The concept of air purification around site personnel is also different in biosafety cabinets and fume hoods. Fume Hoods Exhaust the air, whereas Biosafety cabinets filter the air.

In Fume hoods, there are exhaust fans above fume hoods. They aid in the removal of chemicals and combine them with outside air in the ducting of the fume hood. Then they are released into the air. To remove dangerous moisture from the area, enough air must be available in the space.

In Biosafety Cabinets, High-Efficiency Particulate Air (HEPA) filters are used in all biosafety cabinets to purify the air that enters the site and is released into the environment. However, how they behave depends on the type:

Applications:

As you choose between biosafety cabinets and fume hoods, you should consider the type of materials and/or products your laboratory employees will work with. Personnel must pay attention to pathogenic, volatile, and odorous components since different materials have varied chemical qualities. Biosafety cabinets and fume hoods suggest reducing hazards related to certain factors.

Toxic and Volatile materials:

Consider a work where you use hazardous equipment and chemicals, such as poisonous gasses, combustible materials, chemicals that can melt, fragile substances, and other volatile and toxic substances. Consequently, a fume hood must be installed at your site. However, dangerous and possibly dangerous pathogenic agents and microorganisms cannot be used in fume hoods.

Infectious Microorganisms:

There should be a higher level of prevention for this category. When handling such a chemical, it is important to protect the product, the environment, and the workers. Tools for managing the safe handling of low-risk or even high-risk components are biosafety cabinets. Antineoplastics and human pathogens fall under this category. These processes—which include vortexing open tubes, pipetting, opening caps after centrifuging, sonicating, aspirating with a syringe, etc.—are prone to produce aerosols. Brucella abortus, Mycobacterium tuberculosis, and other airborne transmitted pathogens can be controlled with the aid of biosafety cabinets.

Summarizing the Topic:

Biosafety cabinets and fume hoods are made to shield lab personnel from dangerous substances. However, each offers a distinct kind of protection. Fume hoods shield lab personnel from breathing in harmful vapors and fumes from tests or processes. Biosafety cabinets, on the other hand, are intended to shield lab personnel from dangerous biological substances. To ensure the safety of the laboratory staff and the environment, it is crucial to select the appropriate type of equipment for a certain laboratory application.

Sorry, the comment form is closed at this time.