19 Feb Leak Rate measurement for pharmaceutical isolators

The leak rate is defined as the amount of air lost from a positive isolator or gained by a negative isolator per unit time. It is expressed as % volume loss per hour.

Apart from % volume loss per hour, reciprocal hours, specific pressure decay rates per unit time, etc. are used to measure the Leak rate.

Since isolators are designed to maintain a controlled environment, leak tightness is a critical indicator of the barrier’s quality. Leak tightness must be mentioned during the design stage, and this can be verified during FAT, SAT, PQ, and OQ. The leak rates generally used for isolators are based on ISO 14644-7:2004 and ISO 10648 – 2:1994 standards.

Classes and the applications

There are no rules on the leak rate, however, there are certain guidelines – ISO 14644-7:2004 and ISO 10648 – 2:1994. Following four classes of leak-tightness are specified in the guidelines:

Class 1: 0.05% volume loss per hour – High Containment isolators

Class 2: 0.25% volume loss per hour – Negative pressure aseptic isolators

Class 3: 1.0 % volume loss per hour – Positive pressure aseptic isolator isolators.

Class 4: 10.0% volume loss per hour – Not applicable for pharmaceuticals

It isn’t necessary to follow these specified classes. For example, one can claim 0.75% of volume loss per hour, which is short of being class 2, hence shall be considered in class 3. This is acceptable too, as there are no absolute rules.

Leak-rate measurement methods:

Following methods are used to measure the leak rate.

- Pressure decay Test

- Pressure Hold Test

- Nitrogen Dilution Test

- Parjo and Fosco Methods

Let us see each test in detail-

1. Pressure decay test:

In this method, all the openings/ports of the Isolators are closed and the internal pressure is raised to the test pressure and the change in pressure drop is noted over time. It is easy to perform even with untrained operators.

2. Pressure Hold Test:

In this, the test Isolator is sealed off and the air is supplied through an airflow meter.

The isolator pressure is raised to the test pressure and then that pressure is held steady. The air pressure required to hold that pressure is directly measured through the flow meter and that reading is, of course, the leak rate.

This test is usually suitable for the Isolators with a volume larger than 3m³.

3. Nitrogen Dilution

This test involves filling the Isolator with Nitrogen and holding it at negative pressure. A sensitive oxygen sensor present inside the Isolator follows the increase in oxygen concentration change as the isolator air leaks inwards.

4. Parjo and Fosco Methods

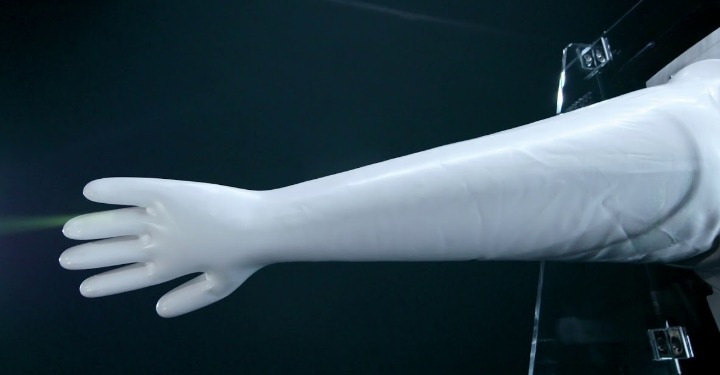

In this, the test equipment consists of a reference vessel inside the glovebox, with a glass tube connected to the top. The tube has a horizontal section into which the soap bubble is introduced. Any leakage of the sealed glovebox will cause the bubble to move along the tube. The speed at which it moves can be used to calculate the leak rate.

The Fosco method replaces the bubble tube with a micromanometer.

A WordPress Commenter

Posted at 13:58h, 19 FebruaryHi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.