10 Oct Difference between Laminar Air Flow and Reverse Laminar Air Flow

A laminar flow system is an essential concept in particulate contamination control. Laminar airflow is defined as air moving in the same direction at the same speed with no or minimal crossover of air streams (or “lamina”). Laminar flow is required in most contamination-sensitive environments, such as dust-free hoods, because it sweeps particles in a uniform direction from the cleanest area under the hood (the filter face) to the exit area, which is typically the sash opening or vents along the back or bottom of the hood.

This design ensures that the cleanest (and germ-free) area is always the upstream area closest to the filter face. Work is generally done in that clean zone, as far away from turbulence-causing obstructions as possible.

Further the Laminar flow is divided into two categories:

- Horizontal Laminar Airflow

- Vertical Laminar Airflow

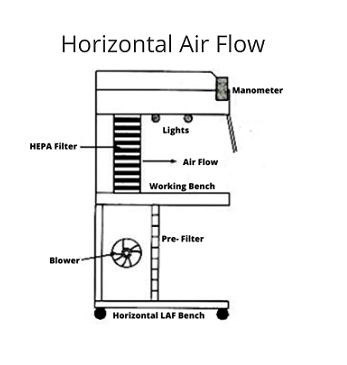

Horizontal Laminar Airflow:

Room air enters the system from behind the HEPA filter, and 99.99% particle-free air is forced across the work surface from back to front. A horizontal-flow hood requires more depth to accommodate the rear-mount filter/fan unit, as well as some extra rear clearance to allow air into the system. Because of the clearance requirements, a deeper bench and more floor space are required than in a vertical flow system.

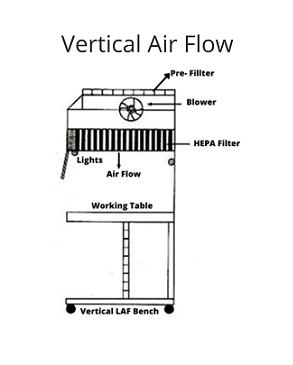

Vertical Laminar Airflow:

The system draws in room air from above the HEPA filter, and 99.99% particle-free air is forced downward toward the work surface. Vertical laminar flow hoods are popular because they closely resemble the design of a laminar flow cleanroom, in which fan/filter units are typically located in the ceiling. Vertical laminar flow reinforces the effect of gravity and sweeps particles out of the enclosure by directing the laminar flow downward, typically through a front access area. Although micro-contaminants have a low mass, most particles eventually settle on a work surface or the floor of a room, and vertical flow helps them get there fast

Reverse Laminar Airflow:

Reverse Laminar Air Flow is a purifying device equipped with a high-efficiency HEPA filter to provide maximum protection from airborne contaminants generated during powder handling operations such as charging, sampling, and dispensing. It works on the principle of re-circulatory airflow, which ensures that powder aerosols are drawn away from the operator and the operating environment, protecting products and providing safe working conditions for personnel. The reverse flow-scavenging pre-filter at the bottom level / table level ensures that aerosolized particles are picked up at the source and do not disperse into the area.

Further Reverse Laminar Airflow is divided into two sections:

- Reverse Vertical Laminar Airflow

- Reverse Horizontal Laminar Airflow

Reverse Vertical Laminar Airflow:

The ULPA or HEPA filter is mounted above the work surface in reverse vertical flow cabinets, creating a taller and deeper workspace. This allows for the use of larger equipment in the work zone without interfering with airflow. It is also simpler to tailor a reverse vertical flow cabinet to the specific requirements of a given application.

Reverse Horizontal Laminar Airflow:

In reverse vertical flow cabinets, the ULPA or HEPA filter is mounted above the work surface, creating a taller and deeper workspace. This allows larger equipment to be used in the work zone without interfering with airflow. It is also easier to customize a reverse vertical flow cabinet to meet the specific needs of a given application.

The main principle behind reverse laminar airflow is that it makes use of negative pressure inside the booth. This pressure prevents the escape of fine powder from the work area to the external environment. The downward flowing direction of air turns out to be very beneficial as it provides full protection to the operator & the product.

Wrapping up:

The key difference between laminar flow hoods and reverse laminar flow hoods is that the former protects items on the work surface while the latter protects operators.

To know more about Laminar Airflow and Reverse Laminar Airflow, connect with us at sales@isovax.in

Sorry, the comment form is closed at this time.