23 Nov Difference between Aseptic and Sterile Condition.

It ought to be obvious saying that in order to reduce the danger of infection, microbial cultures must be handled carefully. Therefore, it is crucial to comprehend the meaning of every terminology used in the explanation of safety measures.

‘Sterilized and Aseptic’ are two of these terms that are frequently used in discussions about safety as well as the production and administration of pharmaceutical products. Although both are often employed for contamination-control, they are actually two distinct concepts.

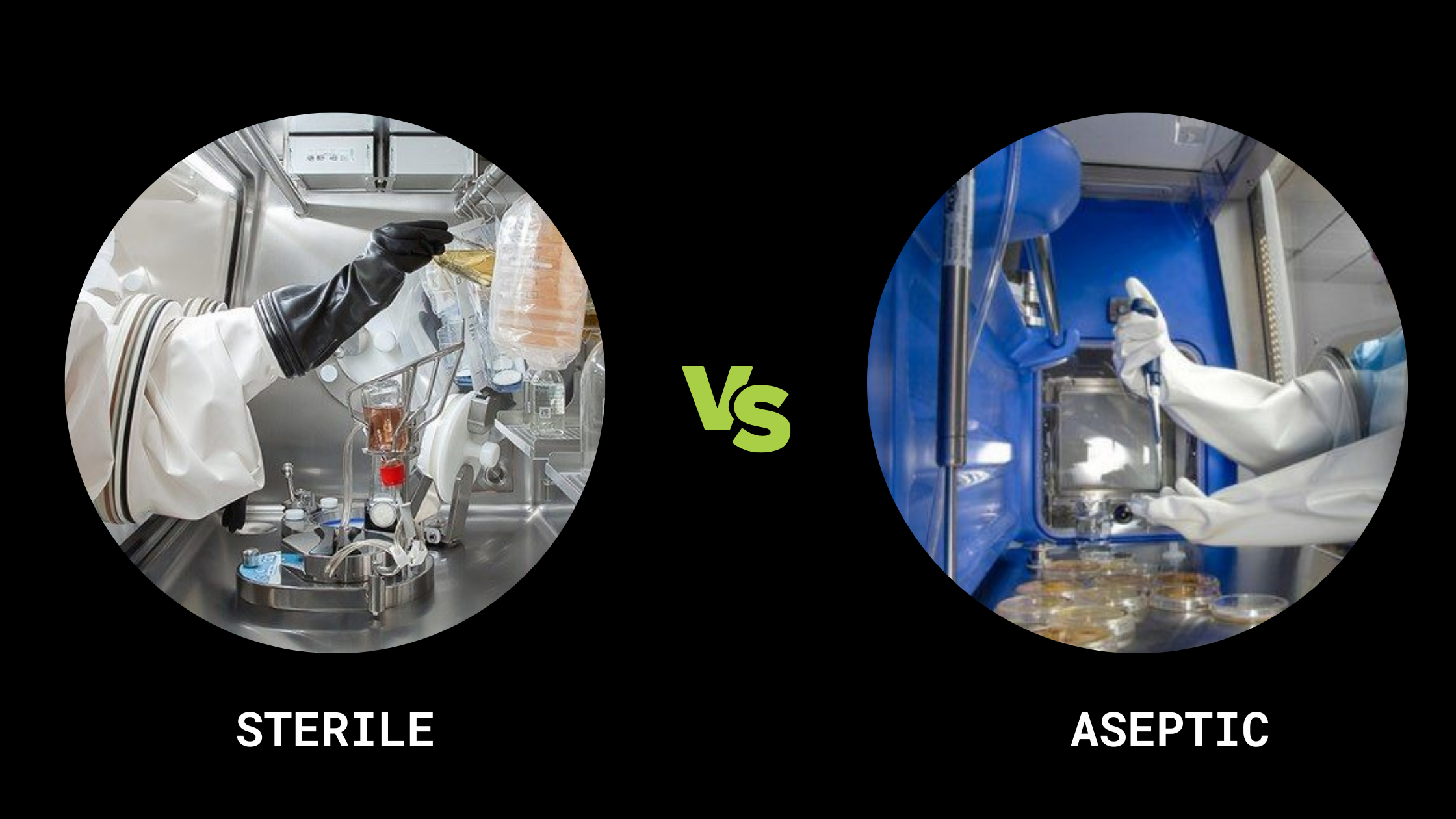

Sterile v/s Aseptic:

Sterile:

Sterile means free of bacteria, viruses, fungus, and spores, it does not discriminate between specific pathogens. A sterilization process seeks to eliminate all live microbes from an environment.

Aseptic:

Aseptic processing does not generate a sterile state; it just preserves sterility. It confines the presence of bacteria, viruses, and other hazardous biological creatures within the allowed restricted place.

Sterilization is a drastic procedure that may be accomplished in a variety of methods. It is frequently used in medical field, such as to clean surgical tools.

Isopropyl alcohol is a widely used local disinfectant. Hydrogen peroxide or peracetic acid droplet foggers can be used to sterilize vast regions. Autoclaves or gamma radiation are often used to sterilize devices.

Because people are efficient carriers of germs, asepsis is crucial for cleanrooms where people operate. It does not ensure total sterility. However, it does so by adopting measures like standardized cleanroom procedures, training, and donning gowns and other protective gear.

In a nutshell, sterilization is the process of getting rid of dangerous bacteria, and asepsis is the main goal of every cleanroom facility that has received ISO certification.

Incase of isolators:

Aseptic process is carried out in compounding isolator, sterile filtration isolator, Sterility test Isolator, CRAB for the Filling Lines. For creating the sterile environment, VHP cycle is carried out within the isolator.

Sterility testing and aseptic processing of pharmaceutical items are examples of aseptic processes. This recommendation focuses on the establishment of a microbiologically controlled environment for aseptic processing of sterile medical goods. In most situations, the principles required to ensure a microbiologically controlled environment for manufacturing are equally applicable to isolators used for sterility testing.

An area is isolated using an isolator for sterile conditioning, which is a bacteriologically sealed enclosure. It is especially designed to guard against environmental or human contamination of the internal spaces. Its atmosphere is variable. A negative isolator can be utilized to manage potentially dangerous intravenous formulations, chemicals, or agents. This is often employed in pharmaceutical research labs. The restricted isolator satisfies the criteria of ISO Class 5 standards and the rigorous standards required by the pharmaceutical industry as a separator chamber for sterile packing.

Application of Sterile and Aseptic Conditions:

Pharmaceutical Application:

In order to avoid infection, aseptic technique is frequently employed in operating areas in both medicine and surgery. In order to maintain an aseptic environment, sterile equipment is employed in operating rooms in both medicine and surgery.

FMCG Applications:

In the packing process, an aseptic approach is frequently employed. A sterile method is frequently used in the canning process to ensure sterility and extend the shelf life of the product.

Summarising the topic:

Aseptic is often used to describe processes and procedures. The major goals of aseptic procedures are pathogen control, operator safety, and providing a barrier when necessary to protect the product and those nearby.

Sterile is more often used to describe clean settings and equipment. All germs present in food, food processing, or in a setting where medical procedures are being performed will be completely eliminated by a sterilization process.

To know more about the comparison between sterile and aseptic condition, get in touch with us at sales@isovax.in

Sorry, the comment form is closed at this time.